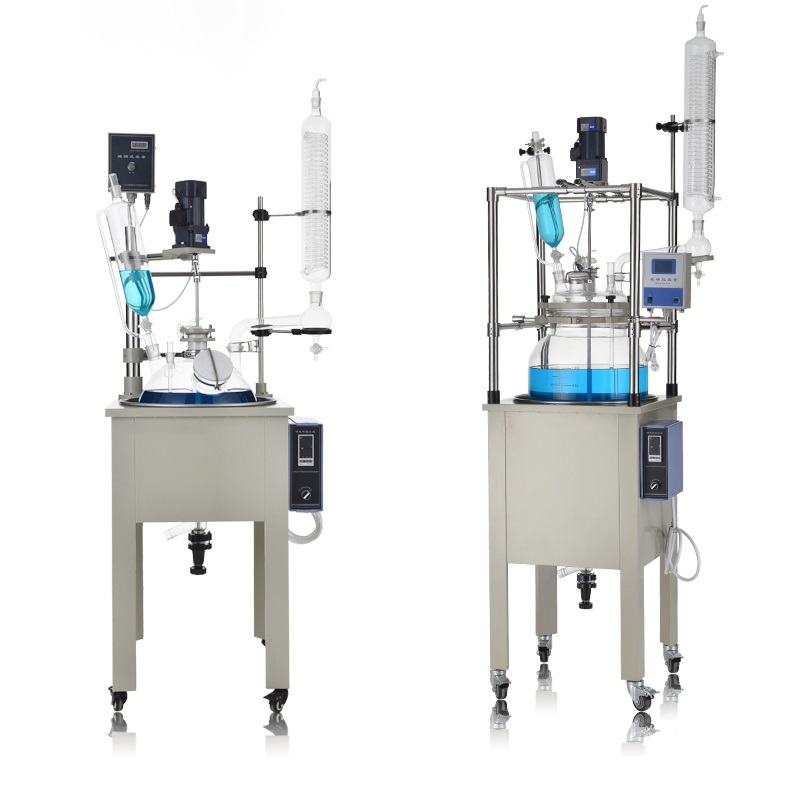

10-200L Single Layer Glass Reactor

10-200L Single Layer Glass Reactor

We have 1-200L single layer,double layer,stainless steel,steel reactor can be choose.And can be customized according to your different requirements. If you have any need please contact us:

Email:Laura@xiaofanequip.com

Whatsapp:008615936214136

Wechat:BEIFAN-Laura

Phone:008615936214136

Description

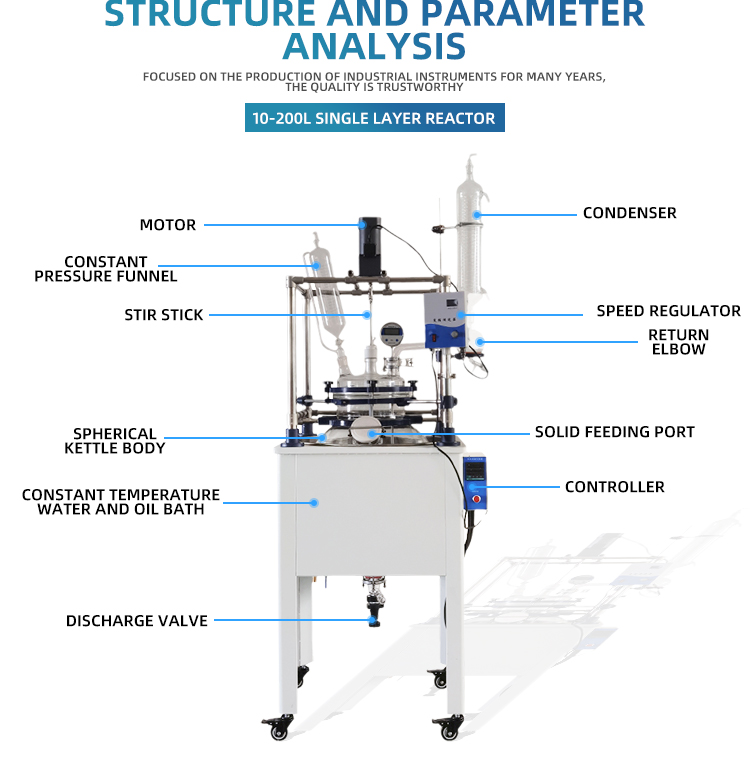

The single-layer glass reactor can provide high-temperature reactions (the highest temperature can reach 300℃); it can also be evacuated to perform negative pressure reactions. The single-layer glass reactor can perform various solvent synthesis reactions under constant temperature conditions. The instrument reaction part is a controllable fully sealed structure. It can continuously inhale various liquids and gases using negative pressure, and can also perform reflux or distillation at different temperatures.

Working principle

The reactor body is directly heated by the silver film heating plate, so that the materials in the reactor are heated at a constant temperature, and stirring can be provided. The materials react in the reactor, and the evaporation and reflux of the reaction solution can be controlled. After the reaction is completed, the lid and motor part of the single-layer glass reactor are mechanically lifted (electric lifting is optional), and the reactor body can rotate 360 degrees to facilitate the dumping and discharging of materials, which is extremely convenient to operate. It is an ideal equipment for modern chemical small and medium sample experiments, biopharmaceuticals and new material synthesis.

Application

Details Image

Specification

| Name | Single layer glass reactor | |||||

| Volume | 10L | 20L | 30L | 50L | 100L | |

| Glass material | GG-17 | |||||

| pot shell material | Spraying antiseptic shell | |||||

| Pot shell size(mm) | 540*440*860 | 640*540*890 | 690*590*920 | 740*640*960 | 640*640*1200 | |

| Inner port material | Stainless steel | |||||

| Inner port size(mm) | 350*220 | 450*250 | 500*280 | 550*320 | 550*650 | |

| Moving mode | Brake type universal corner wheel | |||||

| Shape of reactor body | Ball type | Cylindrical type | ||||

| Port No. of reactor cover | 7 | 6 | ||||

| Distance between discharge to floor | 450mm | |||||

| Temperature range | .-80 to 250degree | |||||

| Vacuum | 0.098Mpa | |||||

| Stirring speed | 0-450rpm | |||||

| Stir rod diameter | 15mm | |||||

| Stir motor | 90W1/3 | 120W1/3 | 250W1/3 | |||

| Heating power | 3KW | 5KW | 8KW | |||

| Overall size (mm*mm*mm) | 600*440*1900 | 700*540*1950 | 750*590*2160 | 800*640*2200 | 730*630*2600 | |

| Package size (mm*mm*mm) | 1100*620*790 | 1220*620*790 | 1220*660*860 | 1440*720*890 | 1900*780*870 | |

| Gross weight(KG) | 63 | 70 | 80 | 90 | 120 | |

| Motor | Low speed booster motor, speed ratio 3: 1 | |||||

| Speed display mode | LCD digital display | |||||

| Temperature display | digital display | |||||

| Seal | ¢70 flange stir port | ¢60 flange stir port | ||||

| Condenser | 100*600mm | 120*600mm | ||||

| Reflux (distillation) device | Return bend with feeding switch, 50# ball mill port | |||||

| Drop adding device | 1L /34 standard | 2L/ 34standard | 2L /40standard | |||

| Pressure release device | standard 34# pressure release valve | |||||

| Temperature tube | standard 24# | |||||

| Solid adding (cleaning) port | ¢120 flange port with PTFE cover | ¢80 flange port | ||||

| Discharge | glass discharge valve, ¢80 flange port | |||||

| Vacuum display mode | Vacuum gauge | |||||

| Mixing connection | universal joint link | |||||

| Stir rod | Anchor type, Stainless steel rod with PTFE | |||||