Wipe Film Molecular Distillation System

Wipe Film Molecular Distillation System

The BMD series scraped film molecular distillation system can be customized according to your different requirements. If you have any need please contact us:

Email:Laura@xiaofanequip.com

Whatsapp:008615936214020

Wechat:BEIFAN-Laura

Phone:008615936214020

Description

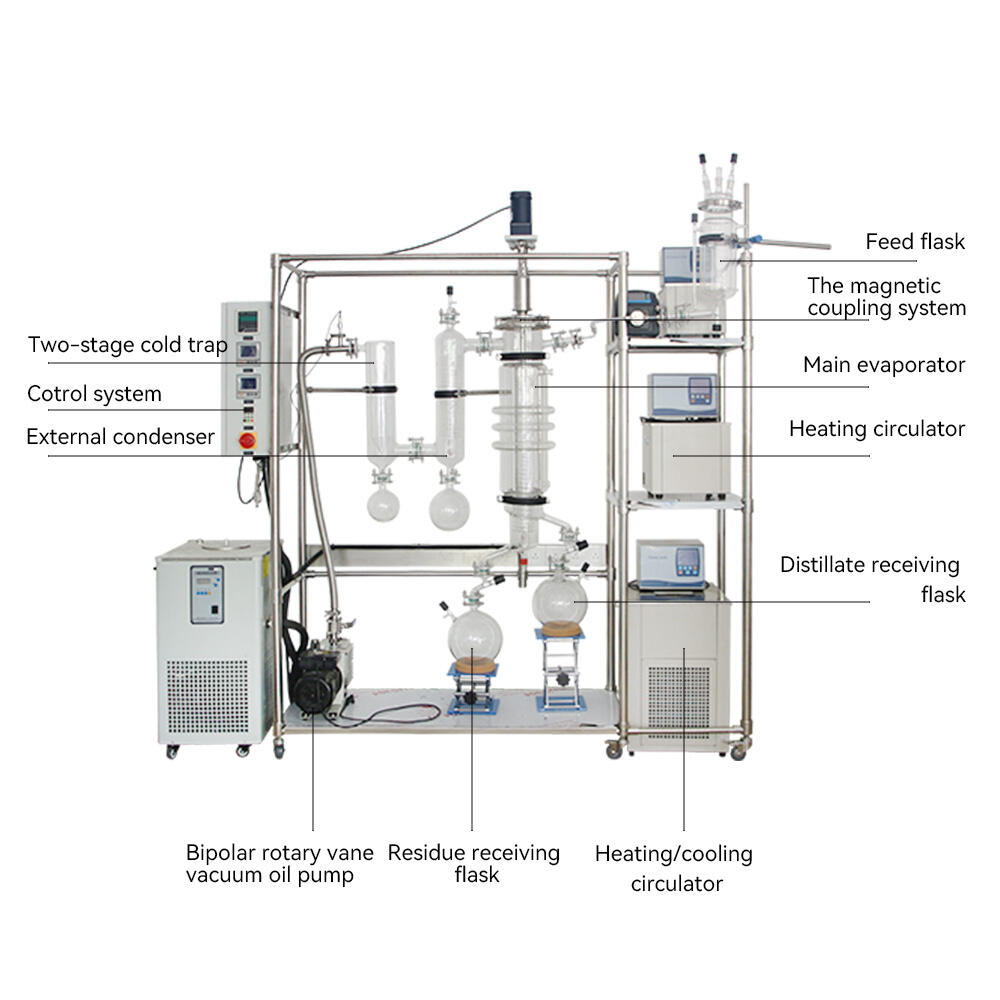

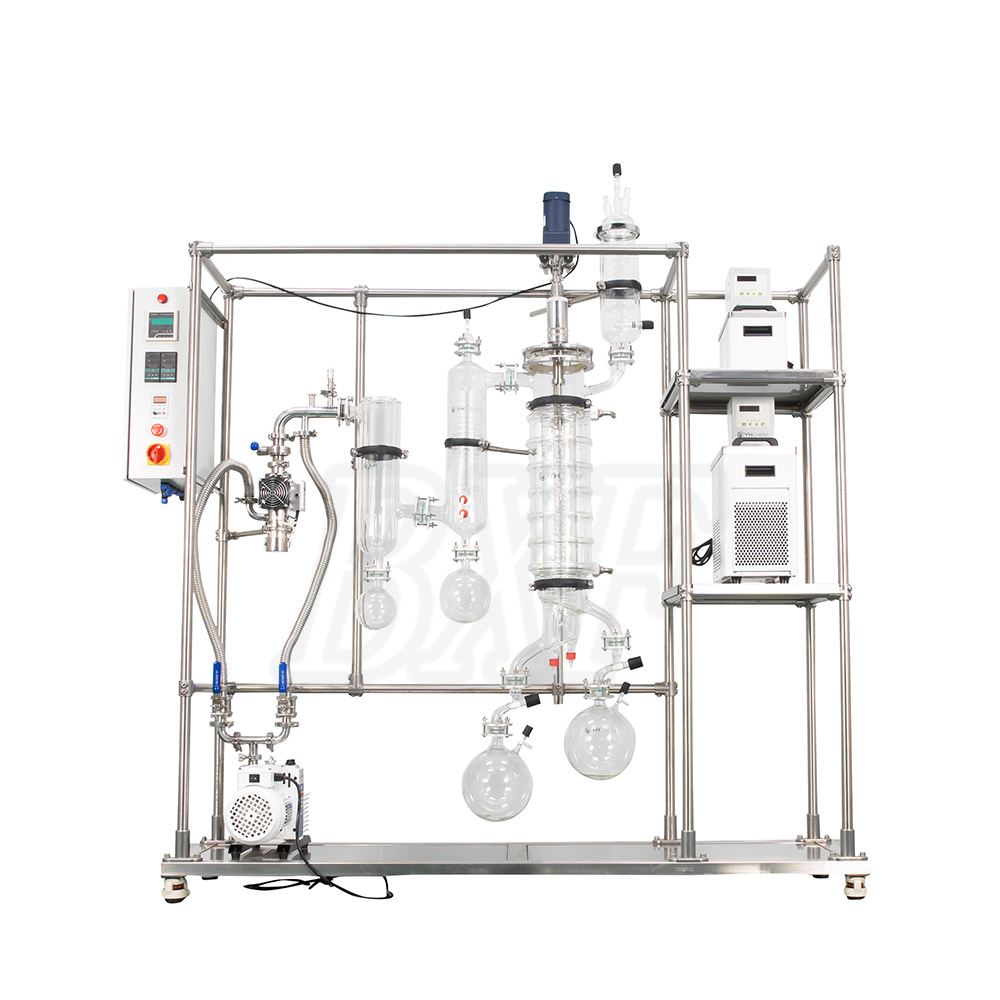

The BMD series scraped film molecular distillation system (borosilicate glass) is a molecular distillation equipment made of high borosilicate 3.3 material, mainly used for efficient and accurate separation and purification of components in liquid mixtures. The system adopts the principle of short-range molecular distillation, and evaporates and recondenses the components in the mixture at a certain temperature through high-temperature heating, thereby achieving separation and purification of the mixture. Its advantages include simple operation, easy cleaning, wide applicability, high purification efficiency, high vacuum, intuitive visualization of the distillation process, and corrosion resistance. It is an ideal choice for experimental research or small-scale production.

Different type

|  |

|  |

Application

Features

● Glass parts are made of high borosilicate 3.3 material, with excellent visibility.

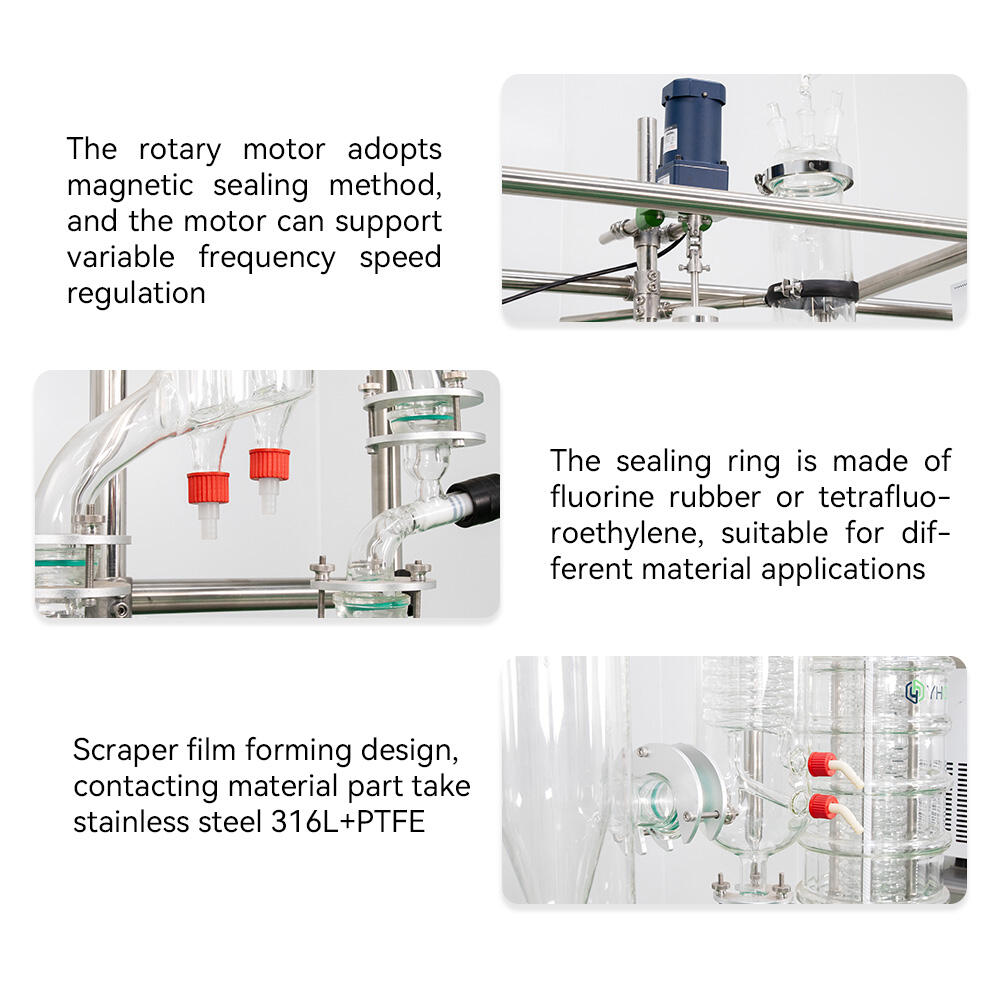

● Magnetic coupling seal can maintain a high vacuum degree to ensure evaporation effect.

● Scraper film design, the part in contact with the material is made of stainless steel 316L+PTFE.

● The sealing ring is made of fluororubber or tetrafluoroethylene, suitable for different material applications.

● The main evaporator adopts a full jacket and full insulation design to ensure material fluidity.

● Digital Pirani vacuum gauge, showing high vacuum degree.

● Multi-scheme structural configuration to ensure different materials and different process requirements.

● Certification: UL, CE.

Details Image

Specification

Model | BMD-60 | BMD-80 | BMD-100 | BMD-150 | BMD-200 |

Feeding rate (L/h) | 0.05~2 | 0.05~3 | 0.1~5 | 0.2~10 | 0.5~15 |

Effective evaporation area (m²) | 0.07 | 0.1 | 0.15 | 0.25 | 0.35 |

Cooling area of internal condenser (m²) | 0.15 | 0.2 | 0.3 | 0.53 | 0.73 |

Feeding flask volume (L) | 0.5 | 1 | 1 | 2 | 3 |

Residue receiving flask (L) | 0.5 | 1 | 2 | 5 | |

Distillate receiving flask (L) | 0.5 | 1 | 2 | 5 | |

Rotation speed (rpm) | 50~300 | 50~500 | |||

Vaccum Level (mbar) | ≤0.01 | ||||

Operation temperature (℃) | ≤300 | ||||

Power supply | 220V,50/60Hz; 1P | ||||